How to Buy/Choose A Good Cello?

~ By Jin Loh

How to Buy A Good Cello?

Understanding how to buy a good cello is important before we proceed to buy any cello in cello shops.

In order to know how to buy a good cello, firstof all, it is useful for cellists to learn about what cellos are made of.

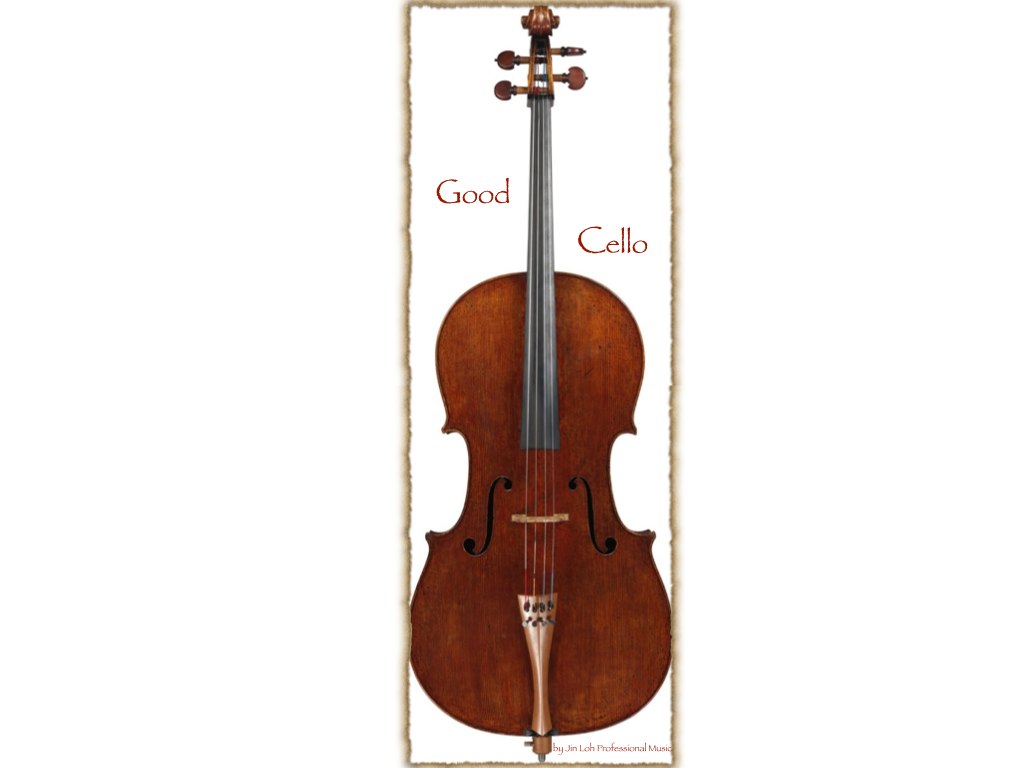

How to Identify Good Cellos by Their Physical Appearances?

1) Good cellos are hand crafted carefully

Good cellos for example, the intermediate cellos and the professional cellos are hand carved or partially hand carved. Especially the branded cellos or the professional cellos, they are normally all beautifully hand carved. Your cello can even be tailor-made by cello makers to suit your specific requirements, for example, which type of cello woods you prefer, your right cello size..etc Just like how we can tailor-made our clothes! :)

Better wood quality and aging tone woods are used to construct good and more expensive cellos, for example, grade AAA ebony woods and maple woods to build different parts of the cellos.

On the other hand, student cellos are mass produced by factories using machines. However, the student cellos are more affordable especially for cello beginners to start with.

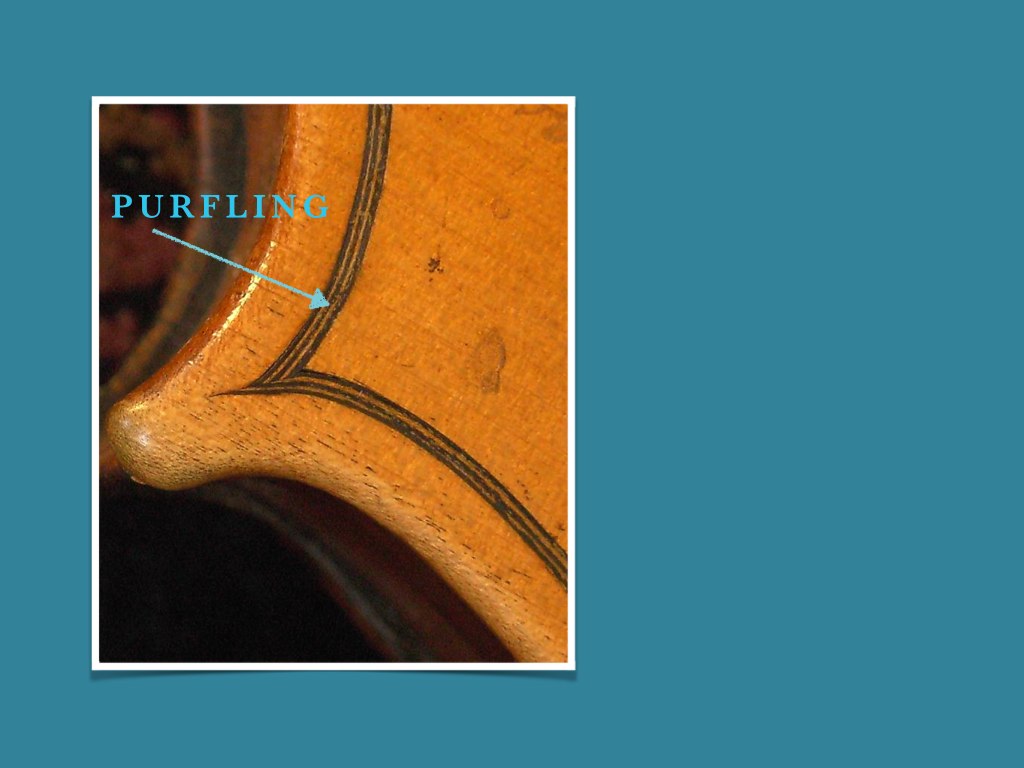

2) Good cellos have real and hand carved “purfling” on the top and back of the cellos

“Purfling” is a decorative inlay found on the top and back part of good cellos. The purpose of having a “purfling” on the top and back part of the cellos are not only for decoration purpose or only to beautify our cellos. :)

“Purfling" is used to protect a cello against any shocks, damages or impacts to the cello. A real, carved “purfling” can protect our cellos and limit harms for example, against weather, dropped, knocked, forming cracks or when we travel around with our cellos.

However, most of the student cellos I have seen are just painted “purfling”, not real or carved 'purfling'! :( Hence, those painted purfling serves only as a decoration…

3) Good cellos should have no cracks on any part of the cello

Please try to spend sometime to look through the cello thoroughly from inside, outside, sideways, front and back before you buy the cello.

Crack cellos have little value...

4) Try moving your left hand thumb along the cello neck a couple of times to check the smoothness

Try to feel if the cello neck surface is smooth. When we play the cello, we often move our left hand thumb up and down to reach different cello positions.

5) Try to check if the cello's fingerboard, bridge, tailpiece and endpin are align or straight

Try to look from the top of the cello scroll till the endpin if the cello is align properly, in a straight line. Please refer to the green arrow (photo on the right) that I have indicated. Try to check if your cello's fingerboard, the cello bridge, tailpiece and endpin are align properly.

I have seen some cellos where the cello's fingerboard and the tailpiece alignment are quite off, not in a straight line. Eventhough the cello tailpiece can be re-adjusted but fingerboard can't! So if your cello's fingerboard and the cello lower part for example, the tailpiece or endpin are not aligned or straight when the cello was constructed, there are nothing much you could do later after buying it..

6) Try to check all the cello pegs if they are perfectly round

If your cello pegs or the cello peg holes are indented or not perfectly round, it will cause slipping cello pegs or sticking pegs problem, resulting the tuning to go off very often. Applying cello peg dope, cello peg drop or chalk on the cello pegs may not be able to solve the problem.

7) Besides the cello's delicate craftsmanship, the cello's quality and its sound quality also depend largely on the types of tone wood being used/selected

I have summarised for example, what are the types of tone woods used in cello construction, how the different types of tone woods affect the cello qualities and why they are used/selected to construct certain parts of cello.

I hope the summary below can help and assist you to choose your cello. :)

Cello Woods and Its Sound Qualities

Cellos qualities are affected by the types and quality of woods being used. Knowing what kind of woods your cello is made of, will help you to decide which cello is a better cello and worth its value.

Generally cellos are made of:

~ Maple Wood

~ Ebony Wood

~ Spruce Wood

~ Poplar Wood

~ Willow Wood

~ Rosewood

~ Boxwood

~ Plywood (Less Expensive cello/Student cellos)

~ Others

Different cello woods have their unique sound characteristics. Thus, this is why sometimes you may noticed some cellos may some brighter or mellower than another cello even in a same cello shop. Different woods are also used in making different parts of the cello.

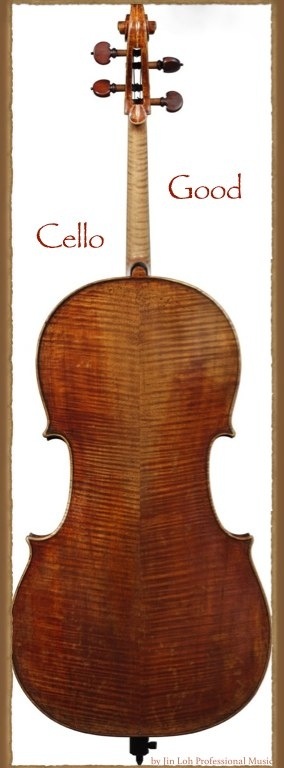

Maple Wood

Better quality cellos for example the intermediate cellos and professional cellos are made of good quality maple woods.

Normally the cello’s scroll, neck and pegbox are carved out of a single piece of maple wood. Maple wood is also used in making most of the cello's side/ ribs, neck and back.

Being a type of tonewood, maple wood is said to carry sound waves well. Unlike Mahogany tonewood, maple wood has higher density, harder and sounds brighter.

Besides cellos, maple wood is also used in making violins, violas and doubles basses.

Ebony Wood

Ebony wood has even higher density compare to maple wood, thus harder.

Ebony Density, g/cc= about 0.7~0.9

Maple Density, g/cc= about 0.5 - 0.6

Although this dense, dark ebony wood is strong, has a lot of strength and does not wear out easily, it is also quite light. Thus, the ebony wood will not make the cello feel very heavy.

Better quality cello’s tuning pegs, nut and fingerboard are normally made of good ebony.

Traditionally, the cello’s tailpiece used ebony.

Spruce Wood

Due to its good sound radiating qualities, spruce is also selected to made the top plate of cello.

Poplar Wood

Some cellos used poplar wood to construct the sides and back part.

Willow Wood

Willow wood is used to construct some cello’s sides and back.

Rosewood

Some cellos used rosewood to make the cello pegs, endpin and tailpiece. It can also be used to construct the cello’s nut and fingerboard.

Boxwood

Just like Rosewood, Boxwood are sometimes used to make the cello’s pegs, nut, fingerboard, tailpiece, endpin.

Plywood

Plywood are thin layers of wood. Plywood are used when constructing less expensive student cellos. Example of the type of plywood used in making cello is the Hardwood (Birch) plywood.

How to Identify A Less Satisfactory/Inferior Quality Cellos By Its Physical Appearances?

Most of the time the less satisfying cellos or the inferior quality cellos are found on student cellos. (Sad to say that...)

We have mentioned previously that student cellos are normally mass produced in factories. They are not hand-made cellos, but machine made cellos. Thus, to make the student cellos look more attractive, some cello makers will paint the cellos with bright coloured paint..etc.

I have seen some orange coloured 'cardboard-made' student cellos before… :@

Despite its less satisfying cello qualities, student cellos are more affordable especially for cello beginners.

Knowing how to choose/identify a good quality cello now, you may be lucky to have a student priced cello but with good cello qualities in it. :)

The Differences Between Good Quality Cellos/Professional Cellos and Student Cellos

Good/Better Quality Cello/Professional Cello

♪ Click here to read cello articles written by Miss Jin Loh ♪